Industrial machine knives are essential tools for many industries, from paper and film processing to metalworking and recycling. This article details what industrial knives are, the material properties that best suit them, as well as how TiC and steel bonded materials improve their longevity and performance.

What are Industrial Machine Knives

Industrial machine knives are specialized cutting tools with a design for performing precise and efficient cutting operations in industrial settings. These blades can serve for cutting, splitting, shearing and converting different materials like metal, plastic, paper, wood, food products and textiles. Unlike handheld industrial knives, machine knives are mounted or built into machinery to operate continuously in demanding environments. Operating conditions often entail repeated impacts, high temperatures, high stress, as well as exposure to abrasive materials. As a result, these knives require careful material selection and design to maintain performance over long periods and reduce downtime.

Types of Industrial Machine Knives

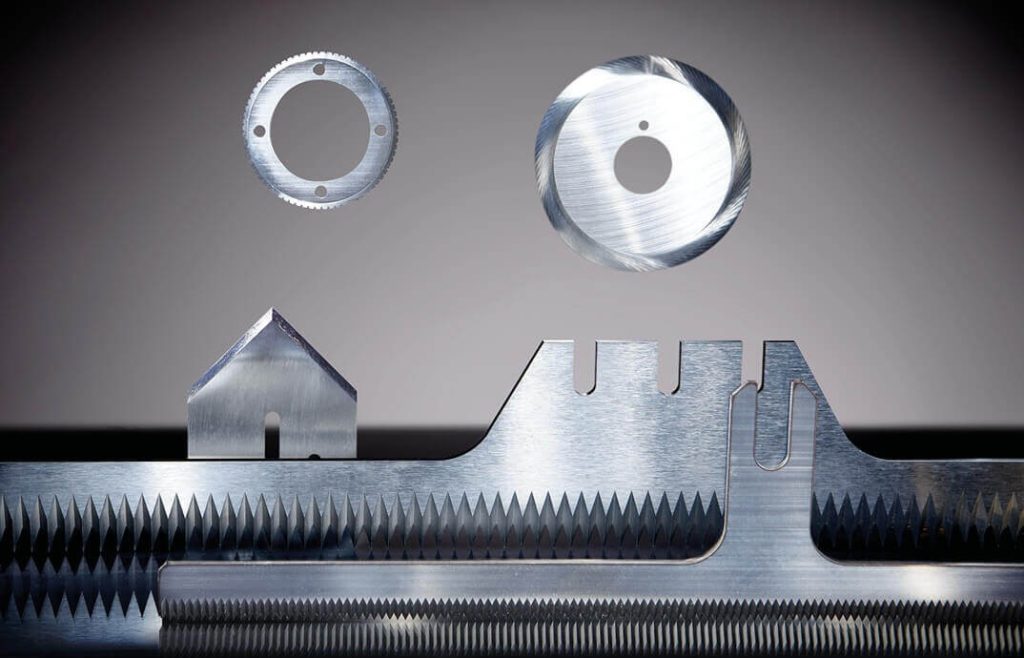

Industrial machine knives come in different shapes and sizes, each tailored for specific applications. Understanding these types can help you select the most suitable knife for your industry. The following sections highlight a few of them.

Straight Industrial Machine Knives

Straight knives are long, straight blades with a design primarily for shearing actions. They are prevalent in metal working, wood working, and paper industries where it is necessary to maintain their sharpness and edge integrity for optimal performance.

Circular Knives

Circular knives are common in industries such as paper, film, foil, rubber, and textile processing. These knives rotate at high speeds to cut materials cleanly and efficiently, making them ideal for continuous operations.

Granulator Knives

These are industrial machine knives that are flat or angled and usually serve in recycling and shredding machines. They chop larger materials into smaller granules, making it easier to process and recycle. These knives are crucial in the plastics and rubber industries, where efficient material size reduction is necessary.

Perforating Industrial Machine Knives

This type of industrial knife creates perforations in materials, producing tearable sections in paper, packaging, and also labels.

Slitter Knives

Generally, slitter or slitting knives are for converting operations to create narrow strips from a wider roll of material. The sharp edges of these knives allow them to slice through various materials with minimal force, thus, ensuring clean cuts. Hence, they are essential in industries including packaging, paper production, and plastic film processing.

Guillotine Knives

Guillotine knives are a variety of straight knives, with a specific design for handling heavy-duty cutting tasks. As a result, they require exceptional strength and durability to perform clean cuts repeatedly. Examples materials being cut include metal sheets, plastics, and cardboard.

Ideal Material Properties of Industrial Machine Knives

The effectiveness of industrial machine knives largely stems from the properties of their materials. Certain characteristics are paramount for ensuring longevity and high performance, as the following sections highlight.

Hardness

A high level of hardness is critical for knives that need to maintain sharp edges despite constant use. Harder materials resist wear and can cut through rugged materials without dulling quickly. However, very hard materials can also be brittle and are prone to chipping or cracking easily. So, there needs to be a balance. Common materials that deliver the prerequisite hardness in machine knives include high carbon steel, tool steel, and high-speed steel.

Toughness

While hardness is essential, toughness is equally important. Toughness measures a material’s ability to absorb energy and withstand chipping or cracking under stress. This property is sometimes measured by its Transverse Rupture Strength (TRS). Materials like D-2 tool steel and M-2 high-speed steel are known for their excellent toughness, allowing them to endure demanding applications.

Edge Retention

This is the ability of a blade to maintain its sharpness over time, therefore minimizing downtime and maintenance costs. The edge retention property of industrial blades can be measured by the CATRA test (Cutlery Allied Trades Research Association).

Corrosion Resistance

Corrosion resistance is the material’s ability to resist rust and degradation from exposure to moisture, chemicals, or other substances. This is very important in an environment where the knives may come in contact with water, food products, or corrosive chemicals. Stainless steel is a good option in these applications because it contains chromium, which forms a protective layer to prevent rust and oxidation.

Wear Resistance

This property ensures that the knife can withstand the abrasive nature of certain materials being cut. Harder materials such as titanium or carbide composites significantly improve wear resistance, hence, extending knife service life.

Other ideal material properties for industrial machine blades are machinability, heat resistance, shock resistance, and chemical resistance.

How TiC and Steel Bonded Materials Improve Industrial Machine Knives

Recent advancements in materials engineering have led to the incorporation of titanium carbide (TiC) and steel-bonded materials. Hence, significantly enhancing the performance and longevity of industrial machine knives.

TiC in Industrial Machine Knives

Titanium carbide (TiC) is a hard ceramic material known for its exceptional wear resistance and hardness. Incorporating TiC or other steel bonded materials into industrial machine knives significantly enhances their performance and longevity. TiC provides the following benefits:

- Enhanced Hardness and Wear Resistance: TiC is significantly harder than conventional steel, improving the wear resistance of the cutting edges. This means that knives coated with TiC can withstand more cuts and last longer under heavy loads.

- Reduced Friction: The low friction coefficient of TiC allows for smoother cuts, minimizing heat generation during slicing. Less heat not only conserves the knives’ edges but also prevents material distortion during processing.

- Corrosion Resistance: TiC coating also enhances the corrosion resistance of the underlying steel. Therefore, making it suitable for environments where moisture and other corrosive substances are present.

Industrial Machine Knives from Ferro-Tic

Ferro-Tic is the ideal material for making your high-quality industrial knives and blades. The very fine, rounded, slippery titanium carbide grains nestled in a tough metal matrix resist dulling and chipping. Therefore, maintaining a sharp cutting edge through millions of cycles. Contact us today and let us work together to deliver the right material in line with your specifications.