Impact strength and tensile strength are both mechanical properties that highlight a material’s response to a force. This article delves into the differences between impact strength vs tensile strength, and the importance of each in high-stress applications.

What is Impact Strength

Impact strength is the ability of a material to withstand a sudden and intense impact without fracturing, cracking, or deforming the material. It is essentially a measure of the material’s toughness. This means that it is a measure of the energy that the material can absorb before it fails. So, it is safe to say that materials with high impact strength are tough, while materials with low-impact strength are brittle. Understanding impact strength is crucial, particularly for materials serving in dynamic or shock-prone environments. For example, it is important for products that experience impact loads in service like automotive parts, helmets, and protective gear. Also, impact strength is important in the design of structures experiencing dynamic loads such as bridges and buildings.

Impact Strength Formula

The measurement of impact strength typically involves a pendulum impact test, such as Charpy or Izod test. In these tests, a notched specimen is struck by a pendulum and the energy absorbed (E) by the specimen is measured. The impact strength (IS) is usually reported in units of energy per unit area, with the area (A) being that under the notch, as the formula below indicates.

![]()

Another way of expressing impact strength is in terms of the thickness of the specimen (t) as the formula below shows.

![]()

What is Tensile Strength

Tensile strength represents the maximum stress a material can endure when subject to a pulling force before breaking. It indicates how well a material can endure tension before undergoing irreversible deformation or fracture. This property is particularly critical in applications where materials are under constant loading such as cables and beams. Factors that influence tensile strength include atomic bonding, microstructure, temperature, and alloy.

How to Calculate Tensile Strength

The following sections highlight the necessary materials, steps and formulae to use in calculating tensile strength.

Materials Needed

- Tensile testing machine.

- Specimen (material to be tested).

- Calipers or Micrometer (to measure specimen dimensions).

- Data acquisition system (to record data).

Tensile Strength Formula and Test Steps

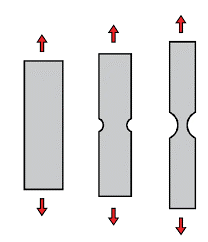

- Prepare the Specimen: Cut the specimen to the required dimensions, typically a dog-bone shape or a rectangular shape with a gauge length.

- Measure the Specimen Dimensions: Use calipers or a micrometer to measure the specimen’s width, thickness, and gauge length.

- Conduct the Tensile Test: Place the specimen in the tensile testing machine and apply a gradually increasing tensile force until the specimen fails or breaks.

- Record the Data: Use a data acquisition system to record the force and displacement data during the test.

- Calculate the Tensile Strength: Use the following formula to calculate the tensile strength (TS).

![]()

Where F is the force magnitude at rupture/failure, and A is the cross-sectional area of the specimen before any strain. During this test, engineers plot a stress-strain curve to provide insights into the material’s elastic and plastic behavior under tension.

Compressive Strength vs Tensile Strength

It is essential to differentiate between compressive strength and tensile strength as they reflect how materials behave under different types of loading conditions.

- Compressive Strength: This property measures a material’s ability to withstand axial loads that tend to shorten the material—pushing it together. Many materials, including concrete and ceramics, exhibit significantly higher compressive strengths than tensile strengths. For example, concrete can sustain loads exceeding 30 MPa in compression, while its tensile strength is often only about 10% of this value.

- Tensile Strength: Conversely, tensile strength deals with resistance to elongation or pulling forces. Materials like metals typically show considerable tensile strength, enabling them to withstand significant loads before failure.

Impact Strength vs Tensile Strength in High-Stress Applications

In high-stress applications, understanding the implications of impact strength and tensile strength is crucial for selecting the right materials for specific uses. While both properties are significant, they serve different purposes.

Dynamic Loading

In applications where materials face rapid, sudden loads (like a car crash), impact strength is vital. For instance, automotive parts such as bumpers and chassis components must exhibit high impact strength to absorb energy during collisions, protecting passengers and structural integrity.

Static Loading

Conversely, in applications involving static or slowly applied loads, tensile strength becomes the focal point. For instance, cables supporting a load in a crane must possess high tensile strength to prevent failure under continuous loads.

Materials Considerations

When designing a structure like a bridge, engineers must account for both tensile and impact strength. The components must be strong enough to bear the weight of vehicles (tensile strength) while also being capable of withstanding impacts, such as debris falling from above (impact strength). Hence, it may be necessary to utilize materials that have be optimized for an application such as the following:

- Composites: Combining materials like carbon fiber and epoxy resin can yield high impact strength and tensile strength, making them ideal for aerospace and automotive applications.

- Alloys: High-performance alloys, such as titanium carbide (TiC) and certain steel grades offer superior tensile strength and impact resistance. Thus, providing suitable options for demanding industrial applications.

Getting the Right Materials with Ferro-Tic

At Ferro-Tic, we are ready to work with you provide the right materials that suits the specifications of your application. We stock a variety of sizes in our most popular grades for fast delivery, including the SK, which provides excellent impact strength. Contact us today and let us get started in delivering the right materials for your project.